Trusted Supplier to Fortune Global 500 Companies

Customized Solutions for Every Industry – From Warehouses to Ports

On-Time Delivery, Reliable Service

- Fast Production & Shipping

- 3-Year Warranty

- Local Support

Types of Rubber Tyred Gantry Crane

From standard single girder and double girder RTGs to straddle carrier solutions, each configuration can be customized based on lifting capacity, material type, working conditions, and site layout—ensuring optimal performance across different industries and daily operation.

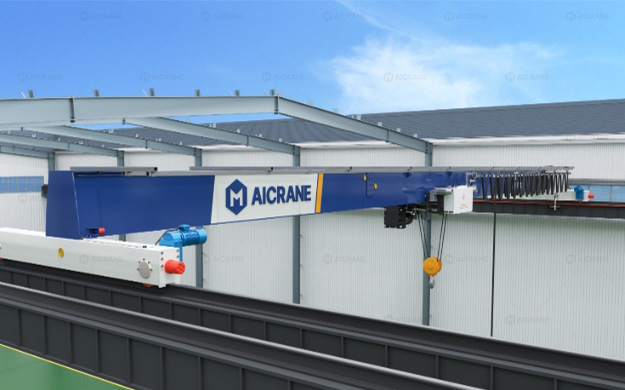

Electric Single Girder Rubber Tyred Gantry Crane

Lifting Capacity:10~25 tons, customizable;

Span: 5~35m, customizable;

Lifting Height:5~15m, customizable;

Features: It combines electric drive with tyre-based mobility for flexible, trackless operation. Powered by a diesel generator or battery system, it is widely used in ports, logistics parks, and factory workshops. It delivers efficient lifting, broad site adaptability, and energy-saving performance.

Get Quote

Electric Double Girder Rubber Tyred Gantry Crane

Lifting Capacity:10~100 tons, customizable;

Span: 5~20m, customizable;

Lifting Height:5~15m, customizable;

Features: It combines electric drive with tyre-based travel for heavy-duty lifting. Designed for handling large loads, it is widely used in ports, logistics parks, workshops, and infrastructure projects. Powered by a diesel generator or battery system, it offering flexible mobility, stable performance, safe operation, and energy-efficient handling.

Get Quote

Hydraulic Rubber Tyred Gantry Crane

Lifting Capacity:10~500 tons, customizable;

Span: 6~20m, customizable;

Lifting Height:5~15m, customizable;

Features: It is a mobile lifting solution powered by a hydraulic drive system. It combines tire-based mobility with high torque output, making it ideal for heavy-duty operations, complex working conditions, and sites without a stable power supply.

Get Quote

Straddle Carrier

Lifting Capacity:50~900 tons, customizable;

Span: 10~50m, customizable;

Lifting Height:5~30m, customizable;

Features: It features full hydraulic transmission with integrated mechanical, electrical, hydraulic, and PLC control systems. It delivers high load capacity, flexible steering, and modular design, ideal for highway, railway, and urban rail transit projects.

Get Quote

Key Advantages – High Mobility & Site Adaptability

Our rubber tyred gantry cranes are engineered for heavy-duty industrial applications, combining high mobility, stable lifting performance, and flexible customization. Trackless operation, advanced steering systems, and modular structural design allow reliable handling across varied site conditions while meeting specific load, space, and operational requirements.

Trackless Operation for Diverse Site Conditions

Trackless Operation for Diverse Site Conditions

Designed for rail-free operation, the RTG can be deployed across workshops, yards, and outdoor industrial sites without ground rail installation, enabling flexible layout planning and material handling.

Multiple Steering Ways for Flexible Handling

Multiple Steering Ways for Flexible Handling

Our RTG supports multiple steering modes, including straight-line travel, diagonal movement, 90° lateral shift, front swing, rear swing, 360° rotation, and Ackermann steering. This significantly improves handling efficiency in narrow aisles and irregular site layouts.

Automated Safety System

Automated Safety System

Our crane is equipped with a comprehensive automated safety system, including photoelectric limit switches, upper and lower hoisting limit switches, and an overload limiter, ensuring operational safety during lifting and traveling.

Highly Customized Design

Highly Customized Design

From crane structure and lifting capacity to steering systems and handling attachments, each RTG can be customized to match your specific materials, site conditions, and operational requirements.

Application Fields

Rubber tyred gantry cranes are typically used for the flexible handling of heavy materials. This equipment finds applications in mechanical manufacturing, infrastructure construction, the steel industry, wind turbine tower manufacturing, and modular housing construction.

Steel Processing Plant

Handling heavy steel products including steel coils, steel plates, steel structures.

Precast Concrete Plant

Lifting and transporting large prefabricated components, including Precast beams, girders, slabs, concrete segments.

Mold Manufacturing Facilities

Handling heavy injection molds during production, maintenance, and storage.

Wind Power & Energy Projects

Handling large and heavy components, including wind turbine components, towers, nacelles, large modules

Container Handling Yards

Stacking, transferring, and repositioning containers.

Global Projects

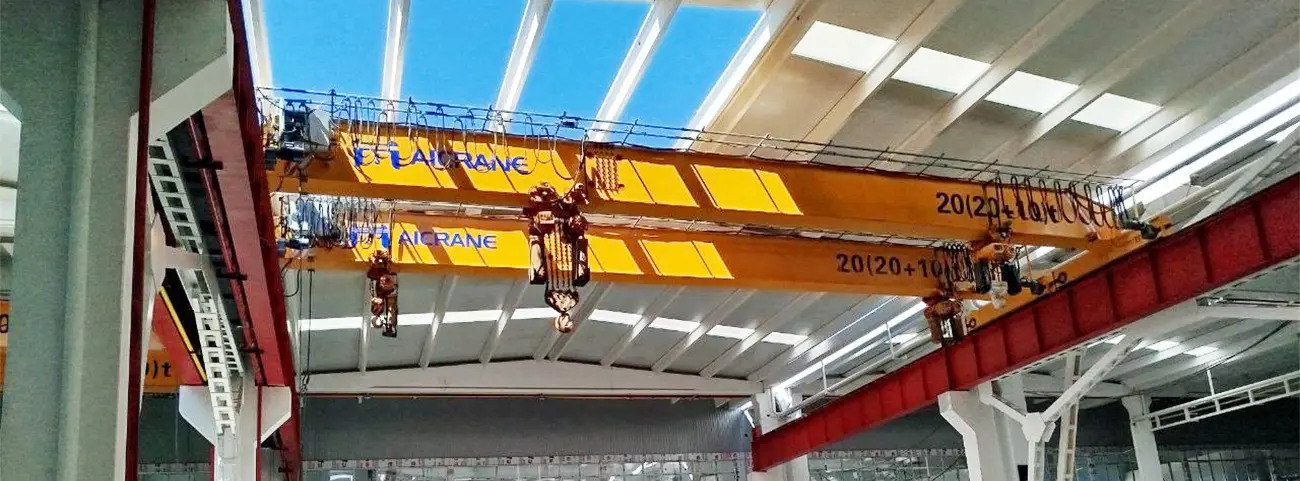

4 Sets of 20/10T HD Overhead Cranes for Mold Handling

![]() Background: A U.S. client in San Antonio needed a crane for large HVAC handling, as existing suppliers offered only costly, non-customizable standard solutions.

Background: A U.S. client in San Antonio needed a crane for large HVAC handling, as existing suppliers offered only costly, non-customizable standard solutions.

![]() Challenge Faced: Limited yard space; High stability requirement; Non-standard lifting conditions;

Challenge Faced: Limited yard space; High stability requirement; Non-standard lifting conditions;

![]() Our Solution: AICRANE delivered a customized DTLS double girder rtg crane (5.5m span, 7.1m lifting height), featuring a compact structural design, dual main-beam configuration for optimized load distribution, and a lifting system tailored to the client’s specific handling requirements.

Our Solution: AICRANE delivered a customized DTLS double girder rtg crane (5.5m span, 7.1m lifting height), featuring a compact structural design, dual main-beam configuration for optimized load distribution, and a lifting system tailored to the client’s specific handling requirements.

Results & Customer Feedback:

- Project completed within agreed schedule.

- Customized solution reduced procurement risk.

- Approximately 20% cost savings compared to the original supplier’s standard solution; customer satisfaction with our quality and service.

Get Your Solution Now